good chain

good advice

“So you’ve read the latest Gartner report, watched 12 webinars, scrolled LinkedIn, skimmed a few HBR, hired a big firm for your “digitalization”, still trying to decipher that deck from the previous strategy consultants, and threw away that expensive software no one wants to use.

Now what?”

Stop chasing a marketed perfection, and aim to be good. We can help, it’s in our name.

Thomas Vandenbogaerde 范登波,

MSc, MEng, CPIM, CLTD,

ASCM instructor

We'd rather be good

than fake perfection

Services we provide

Diagnosis

We’ll tell you what you didn’t know; or did but couldn’t figure how to solve. 30, 60, 90 days road to success but most importantly: what can you start, on your own, right now. Works in an organization or as support to newly appointed C-level.

Execution

Our favorite! Joining your team temporarily to document processes, observe pain points and solve them while taking over part of the daily tasks. Ideal during transitions or staff shortage situations.

Transformation Programme

Planning, launching and supporting transformation programmes: Organisational (growth or layoffs), Supply Chain (Digital) and IT (Stack). It’s less painful when you know what to do (and what not to do).

Software Development

We craft custom Low Code, ETL and BI solutions owned by our clients.

We develop ML/AI for Master data and sourcing and some O365 on-the-shelf solutions for most support functions.

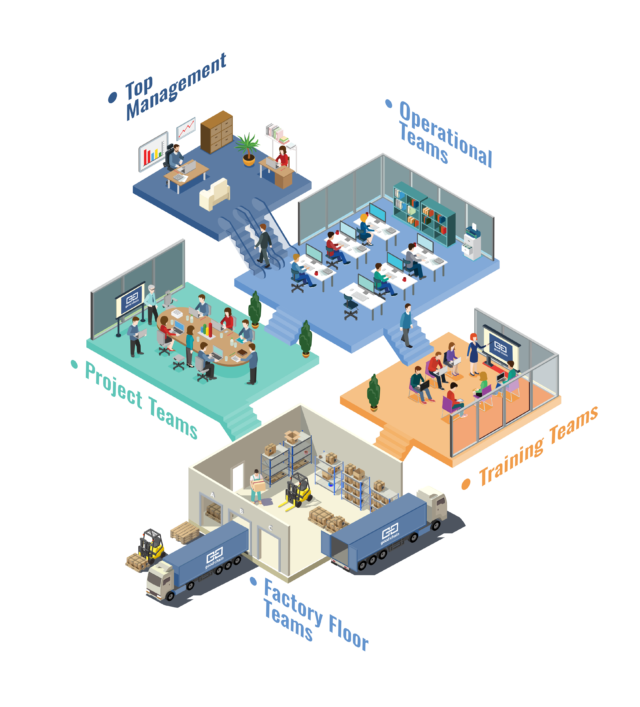

Training

Skills are like seeds for your organization. Sourcing, Supply Chain, Digitial productivity and sustainability. Grow personally and as a team. Hands-on IT training, Business analyst bootcamps or Supply Chain exams coaching.

Diagnosis

We’ll tell you what you didn’t know; or did but couldn’t figure how to solve. 30, 60, 90 days road to success but most importantly: what can you start, on your own, right now. Works in an organization or as support to newly appointed C-level.

Execution

Our favorite! Joining your team temporarily to document processes, observe pain points and solve them while taking over part of the daily tasks. Ideal during transitions or staff shortage situations.

Transformation Programme

Planning, launching and supporting transformation programmes: Organisational (growth or layoffs), Supply Chain (Digital) and IT (Stack). It’s less painful when you know what to do (and not to do).

Software Development

We craft custom Low Code, ETL and BI solutions owned by our clients.

We develop ML/AI for Master data and sourcing and some O365 on-the-shelf solutions for most support functions.

Training

Skills are like seeds for your organization. Sourcing, Supply Chain, Digitial productivity and sustainability. Grow personally and as a team. Hands-on IT training, Business analyst bootcamps or Supply Chain exams coaching.

We are proud

upstream value chain specialists

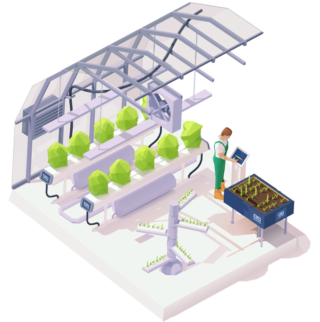

Control your costs and complexityProduct Development

Develop meaningful relationships(Strategic) Sourcing

The world is big, know where you're going! 🌏

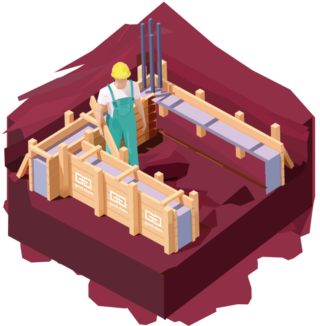

Make it smooth and right first timeManufacturing | Warehousing

Bring failing or immature factories to World Class Manufacturing with support to applying your standards or learning new ones.

Without them, nothing movesSupport Functions

Control your costs and complexityProduct Development

Develop meaningful relationships(Strategic) Sourcing

The world is big, know where you're going! 🌏

Make it smooth and right first timeManufacturing | Warehousing

Bring failing or immature factories to World Class Manufacturing with support to applying your standards or learning new ones.